26 Apr A simple guide to identifying and improving workplace ergonomics: Manufacturing Edition

Written by Safety Professionals at SOS Safety Solutions, Beatriz Colio & Jason Clifford

Ergonomics in the Workplace

Ergonomics in a simpler form is the idea or process of fitting a task or job to an individual. Throughout the manufacturing industry, we encounter ergonomic-related issues on a daily basis.

Whether it is a workstation design or layout, heavy and/or repetitive lifting of items, or even storing and accessing stored items, all involve ergonomics.

Some common injuries related to ergonomics include muscle strains, muscle sprains, and repetitive motion injuries such as carpal tunnel, tendinitis, and more.

According to the Bureau of Labor Statistics, 888,220 non-fatal work injuries occurred in 2019. Ergonomic factors were related to over 250,000 of those incidents.

Common Musculoskeletal Disorders (MSDs) Found in Manufacturing

Lower Back Pain:

One of the top concerns, when it comes to long-term health of employees, is the ever-increasing cases of lower back pain.

According to one study, back pain in general had a direct cost of $25 billion in healthcare costs to employers with the indirect costs surpassing $100 billion each year (AL-Otaibi, 2015).

Additional Resources: https://pubmed.ncbi.nlm.nih.gov/25983601/

Arthritis:

The first use of the term arthritis can be dated back to 1543! According to the CDC, “In the United States, 23% of all adults – over 54 million people – have arthritis.”

Of those 54 million, the CDC reports that 8 million employees claim their arthritis hinders their work performance.

Additional Resources: https://pubmed.ncbi.nlm.nih.gov/30085534/

Carpal Tunnel Syndrome:

According to NHIS Occupational Health Supplement (NHIS-OHS), 2015, Carpal Tunnel Syndrome (CTS) affects roughly 3.89 million people annually across the nation.

Costs for CTS exceed $2 billion annually with treatments ranging anywhere from non-surgical to surgical release.

Additional Resources: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC2397020/

Areas of Concern throughout Manufacturing

- Work requiring prolonged static posture (assembly line)

- Reaching above shoulder height (picking items off a shelf)

- Lifting from below knee height (picking up boxes)

- Trunk rotation (moving items from one table to another)

- Jobs requiring:

- Excessive force (loosening a rusty bolt)

- Excessive repetition (hammering)

How to Prevent Ergonomic Injuries

CONTROL METHODS

The Hierarchy of Controls

A system used in industry to minimize or eliminate exposure to hazards, it is represented as an upside-down triangle with the most effective and protective control at the top.

Elimination and Substitution

The process of physically removing or replacing the hazard. For a process that already exists, major equipment changes and new procedures may be required.

Engineering Controls

Designed to isolate people from hazards. This can include adding material-handling equipment to eliminate manual lifting, changing workstations, or adding ramps or steps to facilitate movement – all highly effective controls.

Administrative Controls

Change the way people work. Finding solutions, such as training employees on ergonomic risk factors, job rotation, and/or implementing pre-shift stretching routines.

Personal Protective Equipment (PPE)

It will help protect employees against minor to severe incidents and is only to be used as a last resort, as employees will still be exposed to the hazard. This includes, but is not limited to, eye, hand, and foot protection.

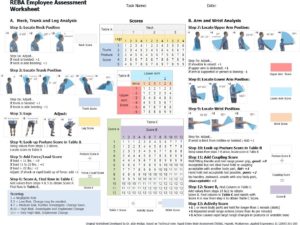

Rapid Entire Body Assessment (REBA)

Evaluates the whole-body working posture and MSD risks associated with job tasks. This single-page worksheet evaluates body postures, forceful exertions, type of movement or action, repetition, and coupling.

This works by the evaluator assigning a score for various body regions such as the wrists, forearms, elbows, shoulders, neck, trunk, back, legs, and knees.

The score will then determine the level of MSD risk and if action and change are required. A score for body regions below ‘7’ may need a change.

However, a score of ‘+8’ requires a change to be implemented. Using tools such as this will aid in eliminating long- and short-term injuries.

For your printable version of the REBA Assessment, please, use the following link and begin assessing your jobs today: http://ergo-plus.com/wp-content/uploads/REBA.pdf

In addition to the external tools implemented by employers to reduce workplace ergonomic risks, a lot of ergonomics comes down to the individual moving properly.

Technique and form are just as important as control methods, especially if we cannot eliminate or engineer out the hazard. We must ensure that our posture is correct to eliminate the possibility of incurring a musculoskeletal disorder.

Always follow safe lifting techniques and remember the key phrases: ‘Lift with Your Legs, Not with Your Back’ and ‘Nose over Toes!’

For additional ergonomic resources, download our whitepaper: Ergonomics in Manufacturing.

No Comments